Plasticizer

Plasticizer

Plasticizer is a general-purpose environmental plasticizer, with excellent gel properties and saponification resistance. It is suitable for many forms of polymers such as PVC and PU.

Chemical components: Alkyl Sulfonic Acid Phenyl Ester (ASE)

CAS NO.: 91082-17-6

Exterior: Transparent , pale yellow clear liquid

Chemical formula: Rso2C6H5(R=C12H25---C18H37)

Health and safety information : Refer to the Safety Data Sheet

The relevant laws of instruction : Alkyl Sulfonic Acid Phenyl Ester is not classified as dangerous according to regulations of the People 's Republic of China on Hazardous Chemicals and European Related States

Specification:

Index Name | Standard Value | Unit | Remarks |

Refractive index | 1.494~1.500 | Nd30 | |

Acid value | ≤0.05 | Mgkoh/g | |

Color value | ≤700 | HaZen, Platinum cobalt color number | |

Density | 1.02~1.06 | g/CM3 | D420 |

Viscosity | 90~100 | Mpa··S | 20℃ |

Water content | ≤0.05 | % | |

Flash Point | 200-215 | ℃ | |

Power point | About ﹣32 | ℃ | |

Boiling range | 211-279 | ℃ | (1333kpa) |

Saponification NO. | Part of the possibility of saponification |

Storage:

Plasticizer is stored in sealed original barrels and dry place because it is sensitive to moisture.

And it can be stored for 2 years even longer under the right stored measure.

Do not contact with iron for long periods of time to avoid discoloration

The raw materials recommendations of transport and storage containers : aluminum or stainless steel (V4A or V2A) barrels with oil resistant coating.

In order to ensure that the Alkyl Sulfonic Acid Phenyl Ester can be easily extracted from the outdoor tanker at low temperatures, the tanker is isolated firstly or slightly heat Alkyl Sulfonic Acid Phenyl Ester with warm water which is the ideal heating medium . But avoid steam heating and the heating coil must be aluminum or stainless steel (V4A).

Solubility:

Dissolved in the general organic solvent but not in water.

Package:

Tanker or metal bucket

Explanation and Application:

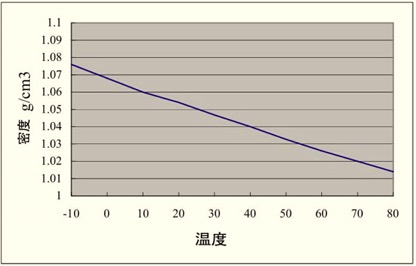

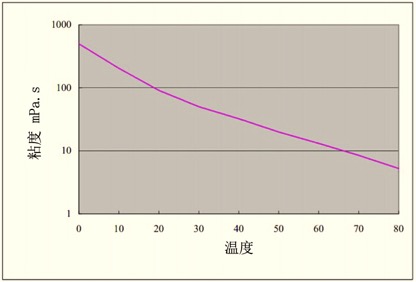

The storage tank, pipeline diameter and pump design are important parameters for density, viscosity and vapor pressure measurement when stored.

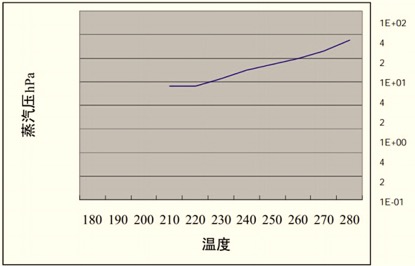

Figures 1 to 3 are data on the above properties .

Figure 1 shows the relationship between density and temperature

Figure 2 shows the relationship between viscosity and temperature

Figure 3 shows the relationship between vapor pressure and temperature

Properties:

Product features: promote gel ability of the majority of polymer materials including PVC, PU , reduce the processing temperature, shorten the processing time, greatly improve production efficiency and reduce energy consumption

Outstanding saponification: compared with DEHP, Alkyl Sulfonic Acid Phenyl Ester has excellent saponification when contacting with water and alkali metals because of its chemical structure.

Good compatibility with PVC, PU, NR, SBR, SBR / BR, IIR, NBR, and CR

Outstanding weather resistance, excellent UV resistance; good electrical insulation and weldability

Application:

Alkyl Sulfonic Acid Phenyl Ester is used as various plasticizers products such as productsin polyvinyl chloride (PVC), polyurethane (PU), natural rubber (NR), Styrene-butadiene rubber (SBR), nitrile rubber (NBR) and chloroprene rubber (CR) etc.

PU-based sealing and bonding systems (single and two-component systems)

Adhesive: PVC glue

Cleaning: cleaning agent of PU foam machine

Calendering categories: automotive leather film, tunnel walls and other industries, such as swimming pool cover, shower curtain, Welding film, electrical insulation film

Slush type: slush toys

Dipped plastic class: PVC disposable gloves and other dipped plastic products

Extrusion: Automotive profiles, fittings, fittings, weather and alkali resistant profiles and blown film

Injection molding: work shoes, industrial products

Coating categories: inflatable products, protective cloth with paint, raincoats, bathroom mats and so on

Coatings: Polyurethane waterproof coating and the use of nitrocellulose paint

Food products: food contact items such as packaging film, food conveyor belt, beverage industry, milk mixing